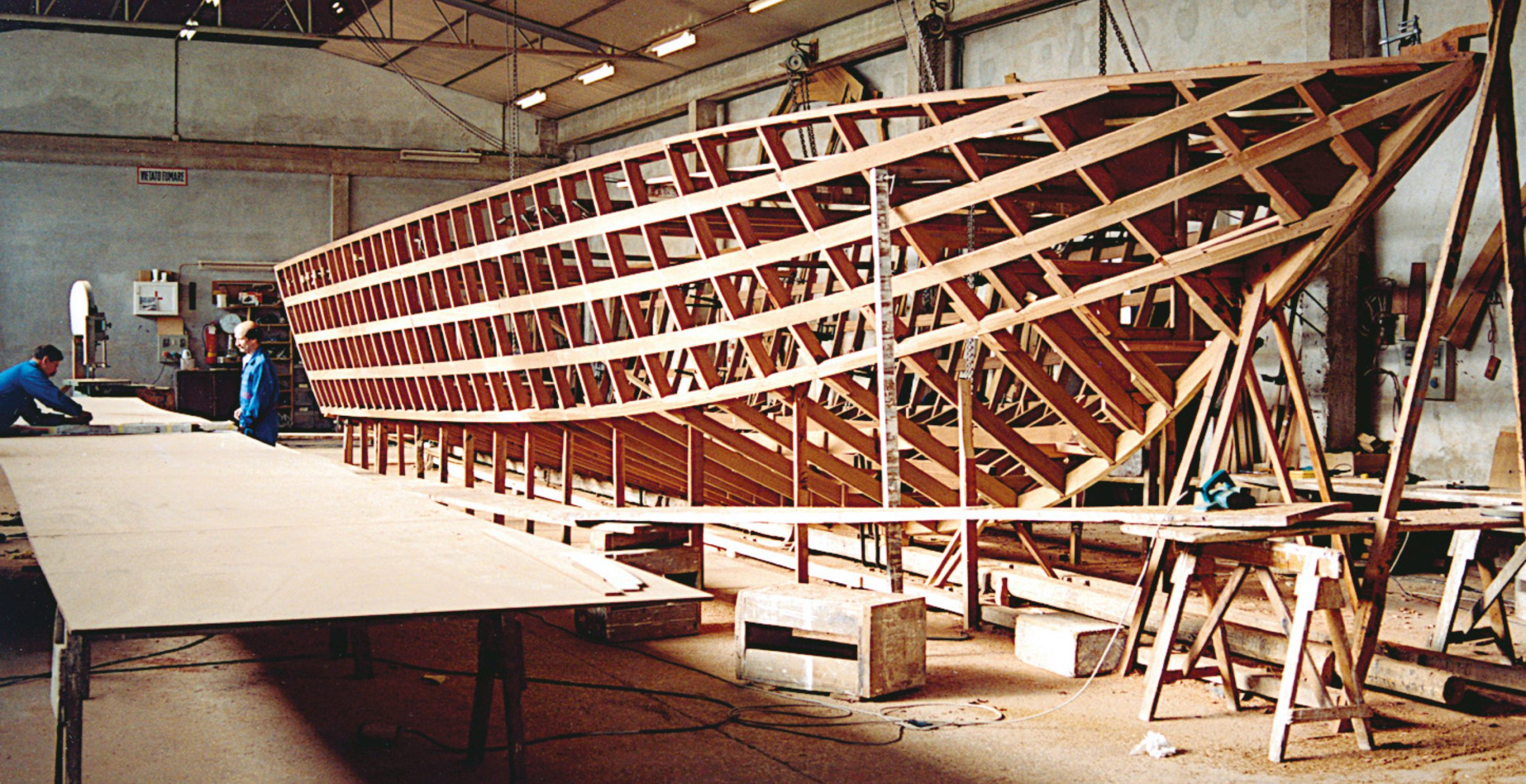

Gli Stradivari del Mare

Sei secoli di costruzioni navali in legno

Il Cantiere Navale Camuffo, il più antico cantiere navale del mondo, universalmente riconosciuto, ha attraverato sei secoli di storia. Da 18 generazioni i Camuffo con le loro imbarcazioni rinnovano i valori di unicità ed esclusività, che gli sono valsi il soprannome di “Stradivari del Mare”.

Storia

Sei secoli di costruzioni navali in legno

interamente fatte a mano

Storia

Una storia irripetibile, ininterrotta e documentata di barche interamente in legno dalle incomparabili prestazioni in mare.